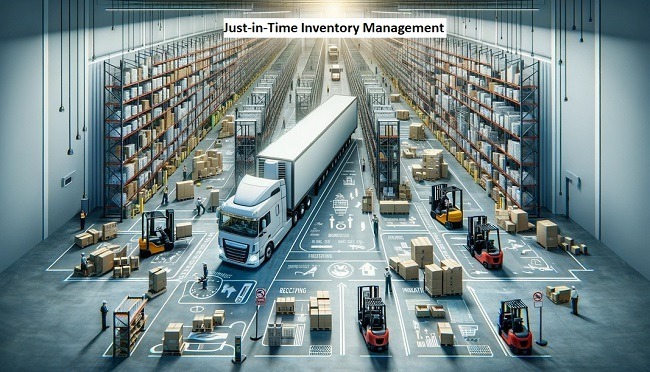

Just-in-Time (JIT) inventory management is a strategy used by businesses to optimize inventory levels and reduce holding costs while ensuring timely delivery of goods. In this comprehensive guide, we’ll explore the principles of JIT inventory management and provide practical strategies for implementation to achieve cost savings and improve inventory optimization.

Understanding Just-in-Time Inventory Management:

Just-in-Time (JIT) inventory management is based on the principle of producing or acquiring goods only as they are needed for production or sale, rather than maintaining large stockpiles of inventory. By minimizing inventory levels, businesses can reduce holding costs, improve cash flow, and respond more quickly to changes in demand.

Benefits of Just-in-Time Inventory Management:

Implementing Just-in-Time (JIT) inventory management offers numerous benefits, including:

Cost Reduction: By minimizing inventory levels, businesses can reduce holding costs associated with storage, handling, and obsolescence.

Improved Cash Flow: With lower inventory levels, businesses free up cash that can be reinvested in other areas of the business.

Enhanced Efficiency: Just-in-Time (JIT) inventory management encourages streamlined processes and reduces waste, leading to improved efficiency throughout the supply chain.

Greater Flexibility: With Just-in-Time (JIT) inventory management, businesses can respond more quickly to changes in demand and market conditions, allowing for greater flexibility in production and distribution.

Key Principles of Just-in-Time Inventory Management:

To successfully implement Just-in-Time (JIT) inventory management, businesses should adhere to the following principles:

- Demand-Driven Production: Produce or acquire goods only in response to customer demand, eliminating excess inventory and minimizing waste.

- Lean Manufacturing Practices: Implement lean manufacturing practices to reduce lead times, eliminate bottlenecks, and improve overall efficiency.

- Supplier Collaboration: Foster close relationships with suppliers to ensure timely delivery of goods and minimize the need for excess inventory.

- Continuous Improvement: Continuously monitor and optimize processes to identify opportunities for further cost savings and efficiency improvements.

Strategies for Implementing Just-in-Time Inventory Management:

Implementing Just-in-Time (JIT) inventory management requires careful planning and execution. Here are some strategies to consider:

Forecast Demand Accurately: Use historical data, market trends, and customer feedback to forecast demand accurately and adjust production schedules accordingly.

Reduce Lead Times: Work closely with suppliers to minimize lead times for raw materials and components, allowing for more responsive production.

Implement Kanban Systems: Use kanban systems to signal when additional inventory is needed, ensuring that production remains aligned with demand.

Invest in Technology: Implement inventory management software and other technologies to track inventory levels in real-time, optimize order quantities, and streamline procurement processes.

Case Studies:

To illustrate the effectiveness of Just-in-Time (JIT) inventory management, consider the following case studies:

- Company A: By implementing Just-in-Time (JIT) inventory management, Company A was able to reduce inventory levels by 30% and achieve cost savings of $1 million annually.

- Company B: Through close collaboration with suppliers and the implementation of lean manufacturing practices, Company B improved production efficiency by 20% and reduced lead times by 50%.

Just-in-Time inventory management offers businesses a powerful tool for reducing costs, improving efficiency, and enhancing overall competitiveness. By adhering to the principles of Just-in-Time (JIT) inventory management and implementing strategic strategies for implementation, businesses can unlock significant cost savings while ensuring timely delivery of goods and services.

Ready to streamline your inventory management and achieve cost savings? Contact Hibosolve for expert guidance and tailored solutions to optimize your supply chain operations.

Leave a Reply

You must be logged in to post a comment.